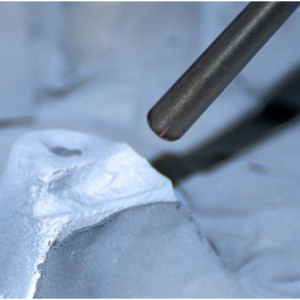

Essentially, metal particles in the form of a powder are introduced into a cold, high-speed gas stream nozzle tube and directed toward a metal or glass substrate. The kinetic energy of supersonically accelerated fine metal particles is used for bonding to produce a new metal coating.

Cold Spray is accepted as a member of the Thermal Spray family and also known as:

CenterLine has chosen to employ the term “Low-Pressure Cold Gas-Dynamic Spray”, which has been selected since it is unique, unambiguous, and communicates the exact nature of the process. Pressure is included in the process designation to distinguish CenterLine’s proprietary system that uses commonly available compressed air rather than more complex systems that require the use of high-pressure inert gas.

The Cold Spray process is ideal for many types of coatings needs, including:

Beneficial characteristics of Cold Spray coatings include:

Visit our Supersonic Spray Technologies website at www.supersonicspray.com for information on this exciting technology and to learn more about CenterLine’s standard and custom Cold Spray systems and services.